Online Mobile Transformer Oil Filter

Online Mobile Transformer Oil Filter Specification

- Overheating Protection

- YES

- Efficiency

- 98%

- IP Rating

- IP55

- Insulation Material

- Glass Wool

- Feature

- Online Operation, Mobile, Efficient Degassing, Dehydration

- Mounting Type

- Mobile Trolley

- Operating Temperature

- Up to 80C

- Power Factor

- 0.95

- Connector Type

- Industrial Coupling

- Surface Finish

- Powder Coated

- Shape

- Rectangular

- Humidity %

- <75%

- Product Type

- Online Mobile Transformer Oil Filter

- Application

- Oil Filtration in Transformers

- Protection Level

- IP55

- Frequency (MHz)

- 50 Hz

- Rated Voltage

- 415 V

- Energy Consumption

- Low

- Output Type

- Filtered Oil

- Color

- Blue

- Dimension (L*W*H)

- 1800 mm x 1000 mm x 1400 mm

- Weight

- 450 kg

- Input Voltage

- 415 V AC

- Size

- Standard

- Phase

- Three Phase

- Material

- Mild Steel

- Connection Type

- Manual Coupling

- Application Suitable For

- Distribution and Power Transformers

- Hose Pipe Length

- 5 m

- Oil Restoring Process

- Degasification, Dehydration, and Filtration

- Breakdown Voltage Improvement

- Up to 70 kV

- Mobility

- Mounted on Four Wheels

- Display Type

- Digital Meters

- Noise Level

- Below 75 dB at 1 m

- Heater Power

- 12 kW

- Maximum Oil Flow Rate

- 1800 LPH

- Degree of Filtration

- Up to 1 Micron

- Control Panel

- PLC Based Control

- Vacuum Pump Capacity

- 300 m3/hr

About Online Mobile Transformer Oil Filter

Online Mobile Transformer Oil Filter manufactured and supplied by us is designed by our team of skilled engineers that make it compatible with medium to high-powered industrial systems. It is installed with a PLC-controlled system that makes it easier to operate this machine without risk of damages. The filtering media installed within this Online Mobile Transformer Oil Filter makes it capable to filter out the micron-sized particles from the oil. The whole unit is encased in a sturdy case that gives excellent protection against harsh working conditions.

Features

- Measuring and displays water content and temperature at inlet and outlet.

- Capable of maintaining moisture level less than or equal to 10 ppm.

- Does not disturb dissolved gas profile

- PLC displays message for saturation and replacement of adsorbent filter.

- Available in three models for different capacity of transformers.

- Optional remote communication protocol for online monitoring of inlet and outlet moisture content, oil temperature etc.

- Gives alarm on finding fault through self-diagnosis and auto shut off in case of abnormalities.

- Optional communication with SCADA through Modbus/RS232 for remote monitoring.

Advanced Oil Filtration Technology

This mobile oil filtration system utilizes degasification, dehydration, and micron-level filtration techniques to restore transformer oil properties effectively. The integrated PLC-based control panel ensures precise operation, while digital meters provide real-time data. Designed for energy efficiency and low noise, it guarantees high purity oil and extended transformer life.

Mobile and User-Friendly Design

The unit is mounted on a four-wheel trolley, allowing easy transport between transformers on-site. With manual couplings and standard hose length, connection and disconnection are straightforward. The powder-coated mild steel body ensures durability and robust protection, supported by IP55-rated construction.

Reliable and Safe Operation

Equipped with overheat protection and glass wool insulation for safety, this filtration unit can handle operating temperatures up to 80C. Its high efficiency, low energy consumption, and ability to function under humid conditions (<75%) make it a reliable choice for servicing transformers in diverse environments.

FAQs of Online Mobile Transformer Oil Filter:

Q: How does the mobile transformer oil filter improve transformer oil quality?

A: The unit employs degasification, dehydration, and high-precision filtration (down to 1 micron) to remove moisture, gases, and particulate contaminants from the transformer oil, improving its breakdown voltage up to 70 kV. This results in enhanced insulation and extended transformer life.Q: What is the typical process for using this oil filtration unit at a transformer site?

A: First, connect the hose pipes to the transformers oil tank using the manual couplings. Start the PLC-based control panel, set parameters, and initiate the filtration cycle. The oil circulates through degasification, dehydration, and filtering stages before being returned clean to the transformerall while the transformer remains online.Q: When should transformer oil be filtered using this equipment?

A: Filter transformer oil when breakdown voltage drops below acceptable limits, or if moisture, dissolved gases, or particulate contamination are detected during routine tests. Proactive filtration can be scheduled during maintenance cycles to prevent insulation failure.Q: Where is this mobile oil filtration unit ideally used?

A: The unit is suitable for distribution and power transformers at substations, industrial facilities, and utility locations across India. Its mobility allows it to service multiple transformers efficiently on-site.Q: What benefits does the PLC-based control panel offer?

A: The PLC-based control panel provides automated operations, real-time monitoring via digital meters, fault detection, and precise control over filtration parameters, ensuring consistent and safe operation during the oil purification process.Q: How does the noise level of this equipment impact its usage in sensitive environments?

A: Operating at less than 75 dB at 1 meter, noise emissions remain low, making the unit suitable for installation and service in areas with noise restrictions or close to operational staff without significant disturbance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

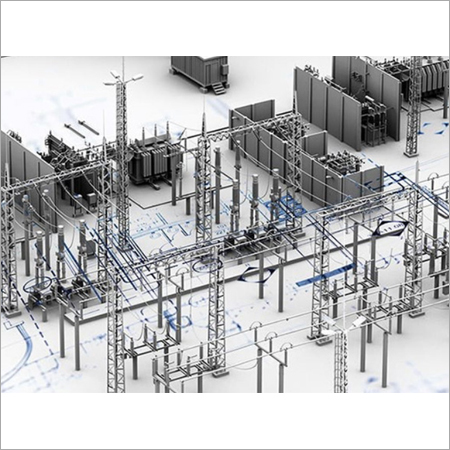

More Products in Substation Solutions Category

Protection Devices

Feature : Short Circuit and Overvoltage Protection

Material : Polycarbonate and Brass

Color : White and Blue

Product Type : Surge Protection Device

Application : Electrical Safety and Equipment Protection

Phase : Single Phase

Digital Substation Devices

Feature : Remote Monitoring, Fault Detection, RealTime Data

Material : HighGrade ABS & Metal

Color : Grey & Blue

Product Type : Digital Substation Device

Application : Power Distribution & Protection

Phase : Three Phase

Substation Automation System

Feature : Remote Monitoring and Control, SCADA Compatible

Material : Mild Steel

Color : Grey

Product Type : Substation Automation System

Application : Industrial Substations

Phase : Three Phase

Transformer Life Enhancement Equipment

Feature : Efficient Transformer Oil Processing

Material : Metal and Polymer

Color : Multicolor

Product Type : Transformer Life Enhancement Equipment

Application : Transformer Maintenance and Life Enhancement

Phase : Three Phase

Send Inquiry

Send Inquiry