Pressed Steel Radiators

Pressed Steel Radiators Specification

- Connector Type

- Custom as per transformer design

- Efficiency

- High thermal efficiency

- Mounting Type

- Vertical mounting

- Operating Temperature

- Upto 100C

- Overheating Protection

- YES

- Feature

- Corrosion-resistant, High heat dissipation, Leak-proof construction

- Surface Finish

- Powder Coated

- Humidity %

- Up to 95% relative humidity

- IP Rating

- IP54

- Shape

- Rectangular

- Product Type

- Radiator

- Application

- Transformers cooling system

- Protection Level

- IP54

- Color

- Dark Grey

- Dimension (L*W*H)

- Height: 1000-1500 mm, Width: 300-1000 mm, Depth: 110 mm approx.

- Weight

- Approx. 35-50 kg depending on size

- Size

- Designed as per requirement

- Connection Type

- Flanged or threaded connections

- Material

- Pressed Steel

- Maintenance

- Low maintenance required

- Fin Type

- Corrugated pressed steel fins

- Environmental Resistance

- Weatherproof, UV Resistant

- Standard

- IS 3347 / IEC 50216

- Usage

- Industrial transformer cooling

- Customisation

- Available as per client drawing and specification

- Medium

- Used with transformer oil

- Compatible Transformers

- Distribution and power transformers

- Test Pressure

- 2.5 kg/cm²

- Lifespan

- 15+ years under standard conditions

- Paint Type

- Epoxy-based or polyurethane paint

Pressed Steel Radiators Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ex-Works

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA)

- Packaging Details

- Appropriately packed

- Main Domestic Market

- All India

About Pressed Steel Radiators

We have marked a distinct position in the market by providing fine quality Pressed Steel Radiators. These radiators are precisely manufactured by making use of supreme grade components and latest technology in adherence with prevalent industry norms at our technologically advanced manufacturing unit. The offered radiators are widely used in oil immersed transformers Parts to ascertain leakages. Available in several technical specifications, the provided Pressed Steel Radiators can be purchased from us at an economical price.

Features:

- Impeccable performance

- Negligible maintenance

- Longer working life

Product details

| Center distance | 800 mm to 3500 mm |

| Type | Standard |

| Application | Automobile |

| Width | 226 mm, 300 mm and 520 mm |

| Standards | IEEMA 9, Din 42559, BSEN 50216 |

Robust Design with Maximum Efficiency

These pressed steel radiators are engineered for optimal thermal efficiency in transformer cooling systems. With high heat dissipation and corrosion-resistant features, they provide reliable cooling, ensuring transformers operate within safe temperature ranges. Their robust powder-coated finish and epoxy or polyurethane paint guarantee protection against UV radiation and harsh weather conditions, significantly extending the radiators operational life.

Customisation and Versatile Application

Our radiators are tailored to suit specific transformer models and project requirements. Options for flanged or threaded connections, various connection types, and dimensions ensure compatibility with diverse transformer designs. The radiators cater to both distribution and power transformers, delivering flexibility for different industrial settings across India.

Low Maintenance and Long Lifespan

Engineered for minimal upkeep, these radiators are built using durable pressed steel with leak-proof construction. The long-lasting paint finish provides resistance to corrosion and environmental wear, offering a lifespan of over 15 years in standard operating conditions. With high humidity resistance and efficient performance up to 100C, they require very little intervention to maintain peak functionality.

FAQs of Pressed Steel Radiators:

Q: How do pressed steel radiators with corrugated fins improve transformer cooling?

A: Corrugated pressed steel fins increase the surface area for heat dissipation, enhancing the cooling efficiency of transformer oil. This ensures transformers maintain optimal operating temperatures, improving performance and longevity.Q: What is the process for customising radiators to client specifications?

A: Customisation involves designing radiators as per the clients transformer drawing and requirements, including dimensions, connector types, and mounting options. Our engineering team collaborates with clients to ensure a precise fit and optimal thermal performance.Q: When should I replace or inspect my pressed steel radiator?

A: Under standard conditions, these radiators last over 15 years. Routine inspections for leaks, paint integrity, and heat dissipation efficiency are recommended annually or as advised by transformer maintenance protocols.Q: Where can these radiators be installed, and what mounting types are available?

A: These radiators are suitable for both indoor and outdoor installation in industrial transformer sites. They are designed for vertical mounting and accommodate various flanged or threaded connections as required by the transformer design.Q: What are the key benefits of using pressed steel radiators for transformer cooling?

A: Key benefits include high thermal efficiency, long service life, weatherproof and UV resistance, low maintenance requirements, and leak-proof, corrosion-resistant construction. These features collectively ensure reliable cooling and reduced downtime.Q: How does the radiator ensure environmental resistance and safety?

A: With a powder-coated, epoxy or polyurethane finish, the radiator resists corrosion, UV radiation, and high humidity (up to 95%). It holds an IP54 protection rating and includes overheating prevention features for safe, reliable operation in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tap Changers Category

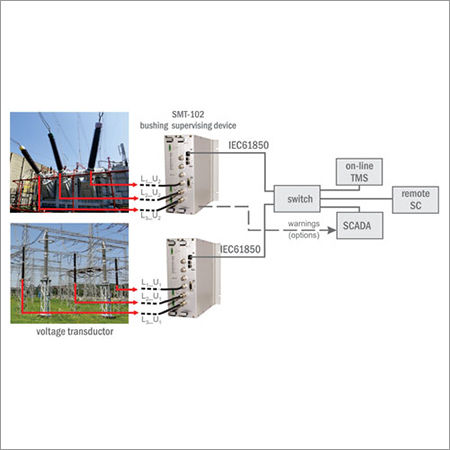

Bushing Monitoring

Minimum Order Quantity : 1 Piece

Product Type : Bushing Monitoring System

Input Voltage : 100240 V AC

Insulation Material : Polycarbonate

IP Rating : IP65

Dimension (L*W*H) : 260 x 175 x 95 mm

Flange Mounted On Load Tap Changer

Minimum Order Quantity : 1 Piece

Product Type : Flange Mounted On Load Tap Changer

Input Voltage : Up to 36 kV

Insulation Material : Epoxy Resin Insulation

IP Rating : IP54

Dimension (L*W*H) : 450 mm x 320 mm x 210 mm

Tapchanger Control and Health Monitoring System

Product Type : Tapchanger Control & Health Monitoring Unit

Input Voltage : 110/230 V AC

Insulation Material : PVC

IP Rating : IP54

Dimension (L*W*H) : 320 mm x 220 mm x 110 mm

High Power Intank Onload Tapchangers (Oltc) for Transformers

Product Type : Intank Onload Tapchanger (OLTC)

Input Voltage : Standard transformer range

Insulation Material : Highgrade insulation materials

IP Rating : IP55

Dimension (L*W*H) : Customizable

Send Inquiry

Send Inquiry