Double Cutter Weld Trimmer

Double Cutter Weld Trimmer Specification

- Weight

- Approx. 2.8 kg

- Technology

- Manual operation

- Color

- Orange and metallic silver

- Technics

- Precision machined

- Type

- Double Cutter Weld Trimmer

- Material

- High-grade steel

- Dimensions

- 240 mm x 85 mm x 65 mm

- Hardness

- HRC 55-58

- Finish

- Polished and painted

- Tooling

- Replaceable double cutter blades

- Surface

- Smooth, rust-resistant

- Packaging

- Box packed with user manual

- Handle Material

- Insulated, heavy-duty plastic

- Cutting Action

- Smooth double-sided blade

- Application

- Weld bead trimming and finishing

- Maintenance

- Low; easy blade replacement

- Maximum Cutting Capacity

- Up to 5 mm weld bead

- Ergonomics

- Anti-slip handle design

- Blade Adjustment

- Adjustable cutting depth

- Safety Features

- Protective finger guard

- Usage

- Suitable for flat and curved surfaces

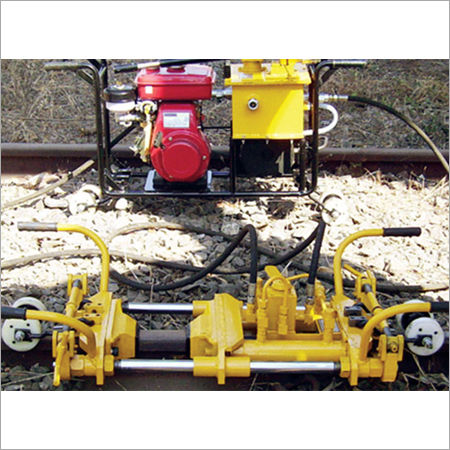

About Double Cutter Weld Trimmer

CTR Manufacturing Industries Private Limited is a Maharashtra, India-based manufacturer and supplier of heavy-duty Double Cutter Weld Trimmer that is designed and developed by our team of skilled engineers which results in high strength and rigidity. It is installed with a sturdy hydraulic system that makes it capable to run efficiently with an assurance of fast and safe delivery. The wheels are fixed to this machine for easy transportation on monorails. Double Cutter Weld Trimmer availed by us can be delivered to our customers as per their demands at a reasonable price range.

Double Cutter Weld Trimmer Features

- Mechanical stoppers prevent fouling of cutting heads after trimming.

- Cutting heads available for various rail sections.

- Wheels provided for easy transportation on monorail.

- Simple to operate with minimum operator training.

Precision Weld Bead Trimming

Engineered for professional weld finishing, the Double Cutter Weld Trimmer features polished, high-grade steel blades with a hardness of HRC 55-58. The adjustable cutting depth allows precise material removal, making it ideal for diverse welding work. Its dual-sided blade delivers a clean, smooth surface while the finger guard enhances operational safety.

Ergonomic Design for Optimal Handling

This trimmer boasts an insulated, heavy-duty plastic handle with an anti-slip design, ensuring comfort and control even during extended use. The protective guard safeguards the users fingers, supporting safe application on both flat and curved surfaces, while its manageable weight (approx. 2.8 kg) further improves ease of handling.

Easy Maintenance and Longevity

Designed for longevity and convenience, the Double Cutter Weld Trimmer offers easy blade replacement, minimizing downtime. Its rust-resistant, polished finish and robust materials ensure durability in demanding environments. Box packaging with a user manual simplifies storage and instruction for users.

FAQs of Double Cutter Weld Trimmer:

Q: How do I adjust the cutting depth on the Double Cutter Weld Trimmer?

A: You can adjust the cutting depth by using the built-in adjustment mechanism, allowing precise control for trimming weld beads up to 5 mm thickness as required for your application.Q: What surfaces can this weld trimmer be used on?

A: The Double Cutter Weld Trimmer is suitable for both flat and curved surfaces, providing versatility for various welding projects and working environments.Q: When should I replace the blades on the trimmer?

A: Blades should be replaced when you notice reduced cutting efficiency or visible wear. The process is straightforward, as the trimmer is designed for quick, easy blade change with minimal tools.Q: Where can I purchase replacement blades or obtain service?

A: Replacement blades and servicing are available directly from the manufacturer, service provider, or supplier based in India. Check your products user manual for specific contact details and ordering information.Q: What safety features does the Double Cutter Weld Trimmer include?

A: This tool features an insulated anti-slip handle and a protective finger guard, helping prevent accidental contact with the blades and improving overall operational safety.Q: How does the double-sided cutting action benefit my weld-finishing process?

A: The smooth double-sided blade ensures efficient, consistent removal of weld beads, reducing labor time and producing a high-quality, finished surface with minimal effort.Q: What maintenance is required for optimal tool performance?

A: Maintenance requirements are lowregular blade inspections and timely replacement, along with keeping the surfaces clean, will help retain the tools rust-resistance and optimal cutting performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Railway Products Category

Joint Straightner

Color : Silver Grey

Technics : Forged and Machined

Material : High Quality Steel

Dimensions : Standard Size (Customized Available)

Tooling : Heavy Duty Tool Head

Surface : Smooth, Rust Resistant

Jack Trolley

Color : Yellow and Black

Technics : Welded Construction

Material : Heavy Duty Steel

Dimensions : Approx. 850 mm x 450 mm x 300 mm

Tooling : Manual Handle with Lever Mechanism

Surface : Smooth, Corrosion Resistant

Traccess System

Color : Silver and Blue

Technics : Precision Engineering

Material : Highgrade Aluminum & Stainless Steel

Dimensions : 2500 mm (Rail Length)

Tooling : Custom Mounts and Fixtures

Surface : Smooth Corrosionresistant

Rail Stressor

Color : Red

Technics : Hot Rolled

Material : Highstrength Steel

Dimensions : 1100 mm x 400 mm x 320 mm

Tooling : Manual and Power Tool Compatible

Surface : Rust Resistant

Send Inquiry

Send Inquiry