Trapped Key Valve Interlocks

Trapped Key Valve Interlocks Specification

- Product Type

- Trapped Key Valve Interlock

- Material

- Stainless Steel

- Gender

- Unisex

- Finishing

- Polished

- Color

- Silver

- Size

- Standard

- Weight

- Approx. 2-5 kg depending on model

Trapped Key Valve Interlocks Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ex-Works

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA)

- Packaging Details

- Appropriately packed

- Main Domestic Market

- All India

About Trapped Key Valve Interlocks

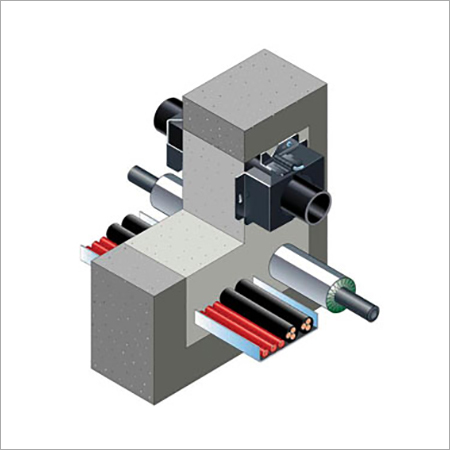

With the assistance of our highly skilled technical experts, we are engrossed in manufacturing and supplying the comprehensive range of Trapped Key Valve Interlocks that used for interlocking valves of tanks, pumps and more. At our advanced production unit, our diligent professionals manufacture these interlocks by making utilization of standard quality material and highly-advanced technology at par with set industry norms of quality. Available in different specifications, these Trapped Key Valve Interlocks can be availed from us at industry leading process.

Trapped Key Valve Interlocks Advantages:

- Immaculate finish

- Ergonomic design

- Efficient operation

Ensuring Process Safety and Integrity

Trapped Key Valve Interlocks mitigate the risk of human error and unauthorized operations in critical process flows. By mechanically enforcing the correct operational sequence, these interlocks reduce the potential for accidents and process upsets in hazardous environments such as chemical plants and oil refineries. The systems reliability makes it an essential safety solution for industrial process isolation.

Customizable Solutions for Diverse Applications

Our trapped key interlocks are designed to suit a wide array of valvesincluding gate, globe, ball, and plug typesand can be tailored to specific operational requirements. The number of keys and lock configurations are customizable, allowing integration into both legacy and new installations. Their versatility makes them suitable for use in manual and automated valve systems alike.

Built for Harsh Industrial Environments

Crafted from corrosion-resistant stainless steel and rated at IP65, these interlocks withstand harsh process conditions, from -20C to +80C, and offer long-term durability. The polished finish and robust construction ensure consistent performance even in corrosive and particulate-laden settings. Their design supports safety compliance in the most demanding operational climates.

FAQs of Trapped Key Valve Interlocks:

Q: How do trapped key valve interlocks enhance safety in process industries?

A: Trapped key valve interlocks enforce a strict operational sequence, ensuring that valves can only be opened or closed in the correct order. This mechanical control prevents accidental or unauthorized valve operations, reducing the risk of process-related accidents.Q: What types of valves are compatible with these interlocks?

A: These interlocks are suitable for fitting on a wide range of manual and automated valves, including gate, globe, ball, and plug valves. Customisation options are available to support different valve types and configurations used in various industries.Q: When should I consider installing trapped key valve interlocks?

A: Trapped key valve interlocks should be considered for any process environment where safe sequential control of valve operations is critical, such as in chemical plants, oil & gas installations, power generation facilities, and industrial automation systems.Q: Where can these interlocks be installed?

A: They are designed for versatile use and can be installed directly onto manual or automated valves across different industrial sites. Their robust construction is suitable for both indoor and outdoor installation, even in challenging environments.Q: What is the process of operating a trapped key valve interlock system?

A: The process involves using a customized mechanical key system. A valve can only be operated when the appropriate key is inserted, which is released only after a previous step in the sequence is completed. This interdependent process ensures that no step is skipped and that isolation or activation protocols are strictly followed.Q: How does customization work for these interlock systems?

A: Customization allows for selection of the number of keys, key configurations, and mounting types, adapting the system to the specific requirements of your site or valve arrangement. This ensures compatibility with unique process flows and operational demands.Q: What are the main benefits of using stainless steel, corrosion-resistant trapped key interlocks?

A: Using stainless steel ensures long-term durability and resistance to harsh chemicals and environments, while the polished finish aids in maintenance. These materials maintain integrity and functionality over extended service, supporting high safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Safety Products Category

Fire Barrier Mortar

Minimum Order Quantity : 1 Unit

Weight : 20 kg or 25 kg per bag

Finishing : Smooth

Size : Bag (20 kg / 25 kg options)

Material : Cementitious Compound

Product Type : Fire Barrier Mortar

Cable Tray Wrap

Minimum Order Quantity : 1 Piece

Weight : Lightweight (varies by size)

Finishing : Smooth/Matte

Size : Customizable widths and lengths

Material : Fiberglass Insulation or Flexible FireResistant Fabric

Product Type : Cable Tray Wrap

Fire Retardant Cable Coating

Minimum Order Quantity : 1 Piece

Weight : 5, 10, 20 kg packaging

Finishing : Smooth finish after curing

Size : Available in 5 L, 10 L, 20 L drums

Material : Special Fire Retardant Polymers

Product Type : Fire Retardant Cable Coating

Safety Interlocks

Minimum Order Quantity : 1 Piece

Weight : 850 g

Finishing : Powder Coated

Size : Standard

Material : Stainless Steel

Product Type : Safety Interlocks

Send Inquiry

Send Inquiry