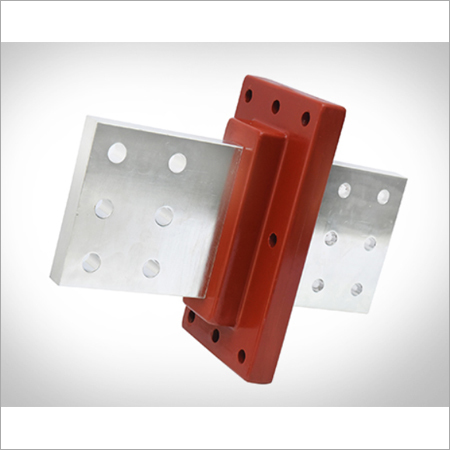

Epoxy Molded Parts

Epoxy Molded Parts Specification

- Product Type

- Epoxy Molded Parts

- Material

- Plastic

- Usage

- Industrial

Epoxy Molded Parts Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ex-Works

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 5 Days

- Packaging Details

- Appropriately packed

- Main Domestic Market

- All India

About Epoxy Molded Parts

We are one of the notable manufacturers and suppliers; betrothed in offering Epoxy Molded Parts that are highly efficient. These parts are most commonly used in automobile industries for a wide range of applications. Offered parts are manufactured under the observation of our diligent experts in complete compliance with predefined industry norms using quality oriented materials and tools. Furthermore, the provided Epoxy Molded Parts are immensely appreciated and preferable in the market for their easy to install feature and durable finish standards.

Features:

- Durability

- Easy to install

- Robustness

Frequently Asked Questions:

Can epoxy be molded?

Several moulding procedures can be successfully completed with epoxy resin. Epoxy resin has been used frequently with an open mould because it may cure at lower temperatures than other materials.

Can epoxy be injection molded?

Several examples of raw materials utilized in an injection molding process are nylon, polycarbonate, acrylic, and acetal. Another example of a famous and high-grade injection material is epoxy. Epoxy is a material that is famously used as a resin for producing plastic injection product.

Is epoxy mold resistant?

Because Master Bond epoxy solutions lack nutrients, they cannot support biological growth such as mould, fungi, or mildew. High humidity, moisture, warm temperatures, UV radiation, and inorganic salts are not harmful to them.

What is epoxy injection used for?

Epoxy injection is an economical method of repairing non-moving cracks in concrete walls, slabs, columns and piers and is capable of restoring the concrete to its pre-cracked strength. Prior to doing any injection it is necessary to determine the cause of the crack.

Why epoxy is used in pharma?

Many pharmaceutical companies choose epoxy because it is non-toxic, seamless, and easy to clean.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Accessories Category

Assembled Bushings

Material : Epoxy Resin Impregnated Paper, Porcelain

Product Type : Other, Assembled Bushing

Usage : Electrical Insulation and Mechanical Support in Transformers

Dimension (L*W*H) : As per specification or drawing

Operating Temperature : 25C to +105C

Weight : Varies with dimension

Transformer Conservator Isolation Valve (Tciv)

Material : Metal

Product Type : Other, Transformer Conservator Isolation Valve (TCIV)

Usage : Used in transformer conservator system to isolate conservator tank from external environment.

Dimension (L*W*H) : Approx. 200 mm x 150 mm x 150 mm

Operating Temperature : 25C to +100C

Weight : Approx. 35 kg

Tapchanger Filter

Material : Metal and Plastic

Product Type : Other, Tapchanger Filter

Usage : Used to filter impurities in tapchanger systems

Epoxy Bushings (EXB)

Material : Epoxy Resin

Product Type : Epoxy Bushings (EXB), Other

Usage : Electrical insulation and support

Send Inquiry

Send Inquiry