Paper Roll Stacker

Price 800000 INR/ Piece

Paper Roll Stacker Specification

- Features

- Low maintenance, safety features

- Handle Type

- Ergonomic

- Belt Type

- High strength polymer

- Rack Capacity

- 500 kg per slot

- Wheel Type

- Polyurethane

- Rotation Type

- Manual

- Control System

- Semi-automatic

- Lifting Speed

- 80 mm/sec

- Motor Type

- Induction Motor

- Forklift

- Compatible

- Condition

- New

- Lifting Capacity

- 2500 kg

- Max. Lifting Load

- 2500 kg

- Max. Lifting Height

- 1600 mm

- Power Source

- Electric

- Power Consumption

- 2.2 kW

- Voltage

- 220V

- Length of Belt

- Standard as per model

- Feature

- Manual & hydraulic lift options

- Attributes

- Robust construction, corrosion resistant

Paper Roll Stacker Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ex-Works

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 1-2 Week

- Packaging Details

- Appropriately packed

- Main Domestic Market

- All India

About Paper Roll Stacker

Our paper roll stacker is a strong and powerful lift, which is engineered to stack heavy paper rolls. It is designed to be cost-efficient, safe and productive. Also it prevents any product damage and ensure precision. The stacker is also ideal for lifting paper reels, plastic rolls, and others. It is reliable in performance, low in maintenance and safe in operation. Compact design and ruggedness are other key aspects. Our paper roll stacker is excellent in capacity, operating and stability. It's an ideal semi-automatic machine for paper, packaging & printing industry.

Features/Benefits of Paper Roll Stacker:

- Durable, rust resistant construction

- Easy to stack the rolls etc.

- Good stability, performance and efficiency

- Ideal for light to medium duty needs

Technical Specification

Model | CRC1 | CRC2 |

Capacity | 1200 | 2000 |

Forklift truck capacity required | 2500 | 3500 |

Min. roll dia. | 410 | 350 |

Max. roll dia. | 1400 | 1600 |

Clamp rotation | 355° | 355° |

Service weight | 685 | 900 |

Efficient Material Handling

Designed for optimal performance in busy warehouses and printing facilities, the Paper Roll Stacker streamlines the storage and movement of heavy paper rolls. Its powerful chain drive and induction motor, combined with 2.2 kW electric power consumption, ensure smooth and reliable stacking. The stackers robust build withstands frequent use, provides stability with a four-wheel base, and utilizes high-strength polymer belts for enhanced durability.

Safe and User-Friendly Operation

Safety is prioritized through features like a foot-operated brake, ergonomic handle, and a semi-automatic control system. Operators benefit from intuitive manual or hydraulic lift options, reliable polyurethane wheels, and enhanced protection against corrosion. The stackers low maintenance design, coupled with ISO certification, guarantees secure and efficient operation across a wide temperature range from -10C to +50C.

FAQs of Paper Roll Stacker:

Q: How does the Paper Roll Stacker operate in warehouse environments?

A: The Paper Roll Stacker utilizes a chain drive system powered by a 220V induction motor, providing reliable and efficient stacking of paper rolls. Its semi-automatic control system makes operation straightforward, while the four polyurethane wheels and ergonomic handle allow easy navigation across warehouse floors.Q: What are the main benefits of using a high-grade steel stacker with a powder-coated finish?

A: High-grade steel construction offers exceptional strength and stability, ensuring safe handling of large loads up to 2500 kg. The powder-coated finish enhances corrosion resistance, prolonging equipment life even in humid or challenging conditions.Q: When should I choose manual or hydraulic lift options?

A: Manual lift is optimal for lighter loads and occasional use, while hydraulic lift is recommended for frequent or heavy-duty stacking tasks. Both options provide flexibility, ensuring that operators can select the most efficient mode for their operational needs.Q: Where is the Paper Roll Stacker commonly used?

A: This stacker is ideal for warehouses, printing units, and facilities involved in paper roll storage and handling. Its compatibility with forklifts and customizable color options make it versatile for various industrial environments across India.Q: What safety features are integrated into the stacker?

A: The machine is equipped with a foot-operated brake, ergonomic handle, and robust four-wheel support for enhanced stability. It also includes safety components compliant with ISO 9001:2015 standards, ensuring operator protection during use.Q: How do I maintain the Paper Roll Stacker for optimal performance?

A: Routine checks on the chain drive, motor, and hydraulic components help preserve performance and safety. Its corrosion-resistant design and low-maintenance structure reduce the need for frequent repairs, supporting prolonged, reliable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Transfer Equipment Category

Vehicle Mounted Scissor Lift

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Equipment Type : Scissor Lift

Feature : Hydraulically operated

Condition : New

Lifting Capacity : 300500 kg

Electric Tow Truck

Price 400000 INR / Piece

Minimum Order Quantity : 1 Piece

Equipment Type : Electric Tow Truck

Feature : Low Maintenance, Robust Construction

Condition : New

Lifting Capacity : 5 Tonne

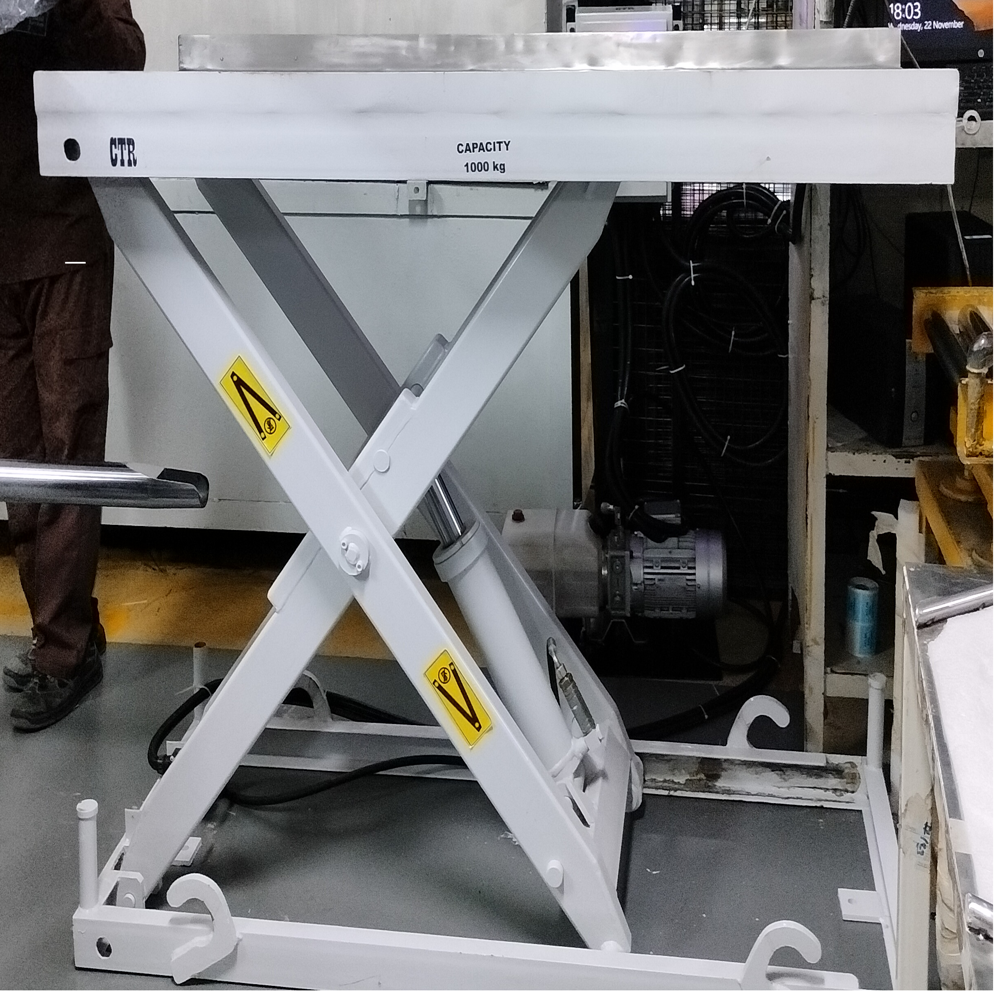

Scissor Lift Table Platform

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Equipment Type : Scissor Lift Table Platform

Feature : Hydraulic Operated

Condition : New

Lifting Capacity : 1000 kg Kilograms (kg)

Hydraulic Scissor Lift Tables

Price 200000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Equipment Type : Material Handling

Feature : Best Quality

Condition : New

Send Inquiry

Send Inquiry