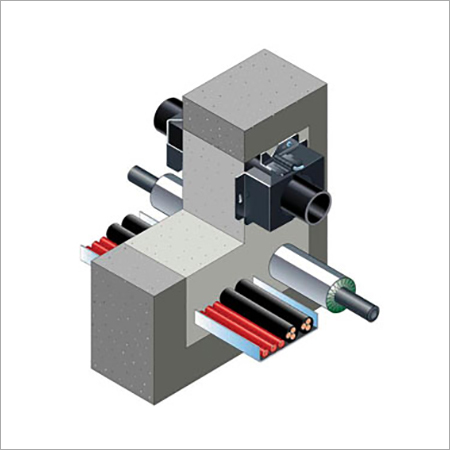

Fire Retardant Cable Coating

Fire Retardant Cable Coating Specification

- Product Type

- Fire Retardant Cable Coating

- Material

- Special Fire Retardant Polymers

- Tape Type

- Coating (Liquid Form)

- Gender

- Unisex

- Finishing

- Smooth finish after curing

- Color

- Off White (dries to white finish)

- Size

- Available in 5 L, 10 L, 20 L drums

- Weight

- 5, 10, 20 kg packaging

Fire Retardant Cable Coating Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ex-Works

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA)

- Packaging Details

- Appropriately packed

- Main Domestic Market

- All India

About Fire Retardant Cable Coating

Backed by our 50 years of industry experience, we are offering excellent quality Fire Retardant Cable Coating to our prestigious clients. The offered coating is processed under the stern supervision of our diligent professionals by making use of supreme grade material and latest techniques at our technically sound production unit as per the global industry standards. This coating prevents the cable from getting heated to a great level and thus, prevents accidents caused by fire and heat. Our provided Fire Retardant Cable Coating is rigorously tested on different measures to meet the set standard of quality.

Fire Retardant Cable Coating Advantages:

- Safe to use

- Easy to apply

- Eco-friendliness

Ultimate Fire Protection for Cables

This fire retardant cable coating provides essential protection for electrical installations, reducing the risk of fire propagation. Its advanced formulation ensures compliance with leading fire safety standards while offering a robust, smooth finish that adheres excellently to both PVC and rubber sheathed cables. Designed for both new and existing infrastructures, its suitable for a wide range of industries.

Quick Drying and Easy to Apply

The coating is engineered for efficiency, featuring a surface drying time of 30 minutes at 27C and reaching full cure in just 24 hours. Supplied in liquid form, it can be smoothly brushed, sprayed, or rolled onto cables, trays, and conduits. After curing, the off-white coating dries to a clean white finish, providing both protection and a professional look.

FAQs of Fire Retardant Cable Coating:

Q: How is the fire retardant cable coating applied?

A: The coating is supplied in liquid form and can be applied using a brush, roller, or spray on clean and dry cables, trays, or conduits. Ensure the area is well-ventilated during application and follow recommended coverage rates for optimal protection.Q: What is the drying and curing time for the coating?

A: The surface dries within 30 minutes at 27C, and the coating reaches its full cure strength in approximately 24 hours under standard conditions.Q: Where can this coating be used effectively?

A: It is suitable for electrical cables, cable trays, and conduits, especially in industrial, commercial, and utility installations where enhanced fire safety is needed.Q: What safety standards does this product meet?

A: The coating is compliant with BS 476 Part 7 Class 1 and ASTM E84 standards, ensuring it offers high-level fire resistance and safety for critical installations.Q: Does the coating affect cable performance or flexibility?

A: No, the coating forms a thin, smooth layer that adheres well to PVC and rubber sheathed cables without compromising their flexibility or electrical performance.Q: What are the main benefits of using this cable coating?

A: Its key benefits include effective fire resistance, non-toxic composition after curing, low VOC emissions, excellent adhesion, professional white finish, and easy application process.Q: How should the coating be stored for best shelf life?

A: Store the product in its original sealed container in a cool, dry, and well-ventilated area to maintain a shelf life of up to 12 months.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Safety Products Category

Fire Barrier Mortar

Minimum Order Quantity : 1 Unit

Size : Bag (20 kg / 25 kg options)

Color : Grey

Weight : 20 kg or 25 kg per bag

Product Type : Fire Barrier Mortar

Material : Cementitious Compound

Cable Tray Wrap

Minimum Order Quantity : 1 Piece

Size : Customizable widths and lengths

Color : Silver/Gray

Weight : Lightweight (varies by size)

Product Type : Cable Tray Wrap

Material : Fiberglass Insulation or Flexible FireResistant Fabric

Transformer Steel Radiator

Minimum Order Quantity : 1 Piece

Size : Customized, Standard Module Widths (e.g. 300mm, 480mm)

Color : Grey / Silver

Weight : As per size / module (Typically 2560 kg/module)

Product Type : Transformer Steel Radiator

Material : High Grade Steel

Trapped Key Valve Interlocks

Minimum Order Quantity : 1 Unit

Size : Standard

Color : Silver

Weight : Approx. 25 kg depending on model

Product Type : Trapped Key Valve Interlock

Material : Stainless Steel

Send Inquiry

Send Inquiry