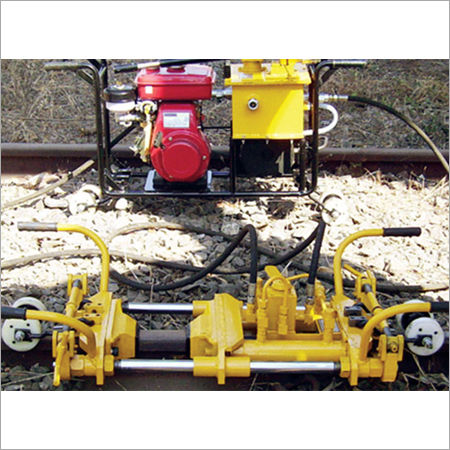

Rail Stressor

Rail Stressor Specification

- Technology

- Hydraulic Action

- Technics

- Hot Rolled

- Color

- Red

- Weight

- 34 Kg

- Type

- Rail Stressing Equipment

- Material

- High-strength Steel

- Dimensions

- 1100 mm x 400 mm x 320 mm

- Hardness

- 50-60 HRC

- Finish

- Powder Coated

- Tooling

- Manual and Power Tool Compatible

- Surface

- Rust Resistant

About Rail Stressor

Stainless steel made Rail Stressor is used for stress relieving of rails. Its working pressure is 57 Mpa and its unit weight is around 360 mm. Its rate of flow is more than 3 l/min. Weight of this Rail Stressor is around 75 kg. This system is used for locking of rail waist without damaging rail head surface. Light in weight, offered Rail Stressor simplifies pulling force of rail. User friendly mechanism, long working life, ergonomic appearance and quick fitting method are some of its key aspects.

Rail Stressor manufactured and supplied by us is specially designed for the adjustment of gaps in between the ends of rails to reduce rail stressing and makes it easier to weld. This machine is capable to produce a pull force of up to 78 tonnes. This hydraulically powered unit is made up of industrial standards that result in high working efficiency. Rail Stressor does not require special tooling for the installation of this unit. Buy from us this device at a reasonable price range.

Enhanced Rail Maintenance Efficiency

Engineered for professional rail operations, our Rail Stressor ensures effortless pre-stressing and de-stressing of rails. Its advanced hydraulic system provides powerful force while the portable design enables quick set-up and relocation, drastically cutting downtime during track maintenance tasks. The low-maintenance mechanism and rugged build contribute to reliable performance in diverse environments.

Safety and Compliance Assured

Each unit features overload protection and is built from high-strength steel with a rust-resistant finish. Rest assured, our Rail Stressor is compliant with international railway standards, safeguarding operators and railway assets while promoting best practices on-site.

Comprehensive Support and Accessories

We supply every Rail Stressor with essential hydraulic hoses, connectors, and a carrying case, ensuring immediate usability on trackside projects. Our team in India backs every purchase with service, support, and guidance, making us a reliable manufacturer and supplier nationwide.

FAQs of Rail Stressor:

Q: How is the Rail Stressor operated during track maintenance?

A: The Rail Stressor can be manually or remotely operated via its hydraulic pump, allowing precise control during pre-stressing and de-stressing procedures on railway rails.Q: What benefits does the lightweight, portable design offer?

A: Weighing just 34 kg and supplied with a carrying case, the lightweight and portable construction ensures easy transportation and fast deployment, even in challenging outdoor and trackside environments.Q: When is the Rail Stressor typically used on railway tracks?

A: It is used during rail installation, repair, and maintenance activities where tensioning (pre-stressing) or releasing stress (de-stressing) is necessary to ensure rail performance and safety.Q: Where can the Rail Stressor be effectively utilized?

A: This equipment is ideal for outdoor use, specifically at railway track sites, thanks to its rust-resistant, durable design crafted for harsh environments.Q: What accessories are included with the Rail Stressor?

A: Each unit is equipped with hydraulic hoses, robust connectors, and a carrying case, facilitating immediate and effective use upon delivery.Q: How does the overload protection mechanism contribute to safety?

A: The built-in overload protection prevents force from exceeding the recommended threshold, safeguarding both the operator and the railway infrastructure.Q: What are the maintenance requirements for the Rail Stressor?

A: Designed with ease in mind, the Rail Stressor requires minimal maintenance, ensuring long-term, trouble-free operation under regular railway usage conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Railway Products Category

Joint Straightner

Weight : Approx. 2030 kg

Material : High Quality Steel

Dimensions : Standard Size (Customized Available)

Hardness : 4550 HRC

Finish : Others, Corrosion Resistant Coated

Surface : Smooth, Rust Resistant

Traccess System

Weight : 4.8 kg

Material : Highgrade Aluminum & Stainless Steel

Dimensions : 2500 mm (Rail Length)

Hardness : 5060 HRC

Finish : Others, Anodized & Powder Coated

Surface : Smooth Corrosionresistant

Jack Trolley

Weight : Approx. 4050 Kg

Material : Heavy Duty Steel

Dimensions : Approx. 850 mm x 450 mm x 300 mm

Hardness : High Tensile Strength

Finish : Others, Powder Coated

Surface : Smooth, Corrosion Resistant

Double Cutter Weld Trimmer

Weight : Approx. 2.8 kg

Material : Highgrade steel

Dimensions : 240 mm x 85 mm x 65 mm

Hardness : HRC 5558

Finish : Others, Polished and painted

Surface : Smooth, rustresistant

Send Inquiry

Send Inquiry